As the world moves towards greater use of renewable energy, the storage and conversion of this energy used in everyday homes is being transformed. In this article, we will highlight a presentation by Jacob Mueller, senior technologist in Sandia National Laboratories' Energy Storage Technologies and Systems Division, on the key trends and challenges involved in this transformation, which highlights the role of power electronics and energy storage.

Power grid energy storage

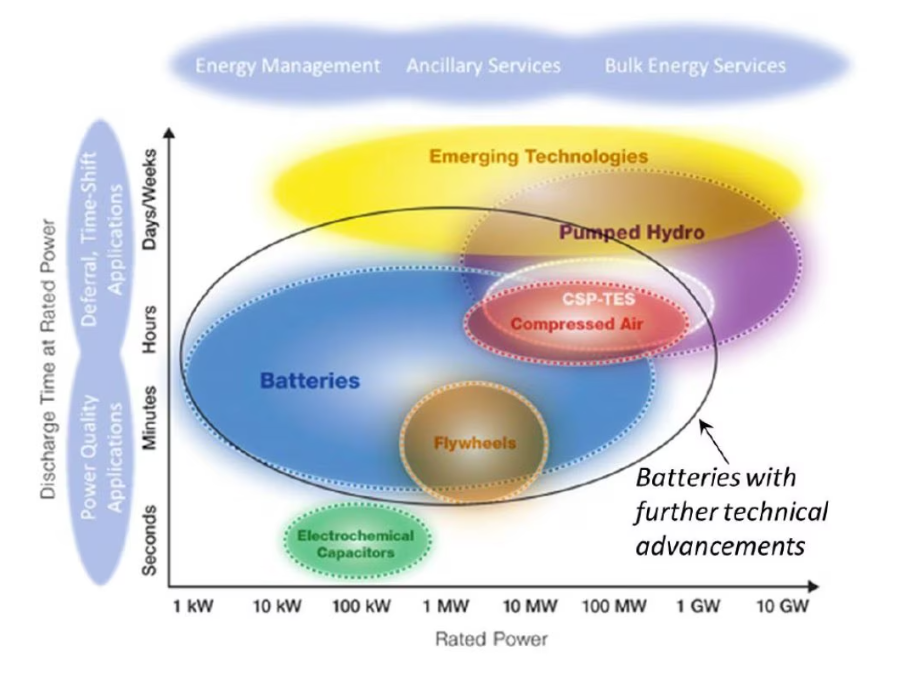

Two-way energy storage systems are able to absorb energy and store it for a period of time before sending it back as electrical energy. It can take many forms, as shown in Figure 1. Variable renewable energy sources such as wind and solar power are driving the development of battery storage systems. A distributed approach that uses smaller batteries at the source of power generation (called distributed energy DER) could make the grid more flexible and reliable. Current battery technology is mainly suitable for short-term energy storage, which ranges from a few seconds to a few hours. Methods such as pumping water power, compressed air, and thermal energy can provide a few hours to a day of storage, but are often limited by natural resources and terrain. As Figure 1 shows, there is currently no off-the-shelf solution for seasonal long-term energy storage.

Figure 1: Relationship between energy storage technology and power and discharge time

Lithium-ion battery energy storage systems (BESS) dominate battery energy storage technology. Examples of large-scale installations are AES 120MWh BESS in Escondido, California, and Tesla 129MWh systems in Australia. Figure 2 shows trends in the increase of large-scale battery capacity in the United States from 2003 to 2020 and from 2021 to 2023. This shows that both independent and co-addressed energy storage systems are accelerating growth.

Figure 2: Large-scale battery storage growth trends in the United States

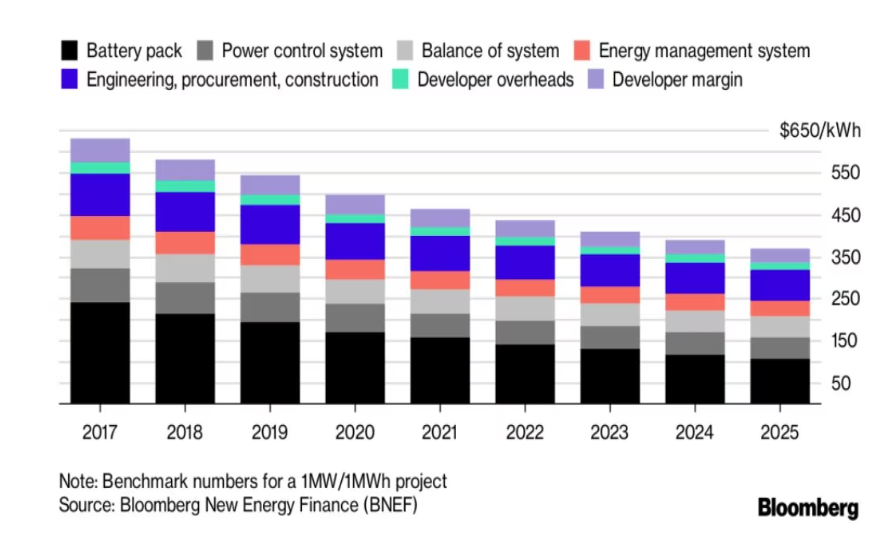

As Figure 3 shows, while the price of batteries is falling significantly, the total cost of BESS also includes several other components, such as a power conversion system (which contains a two-way inverter), an energy management system that provides security and data logging control, as well as container, distribution and HVAC/ thermal management, among others.

Figure 3: BESS price action

Power electronic system

Power electronics systems (PES) provide two key functions in the grid:

● Efficient conversion between different types of energy, such as DC to AC;

● Control the flow of electrical energy.

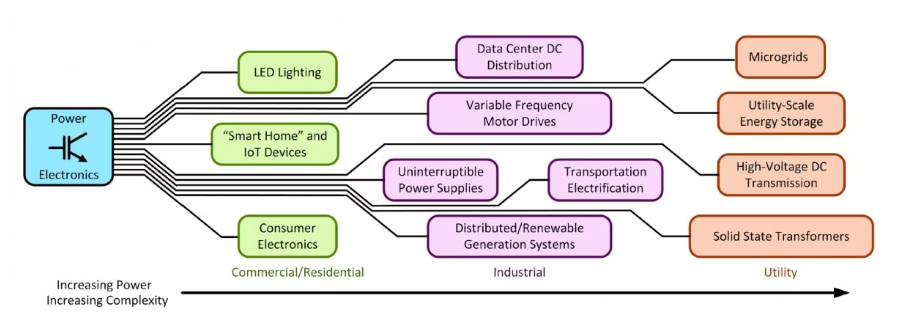

Figure 4: The role of power electronic systems in energy storage and distribution

As shown in Figure 4, PES is required for the entire process from power generation, transmission to distribution.

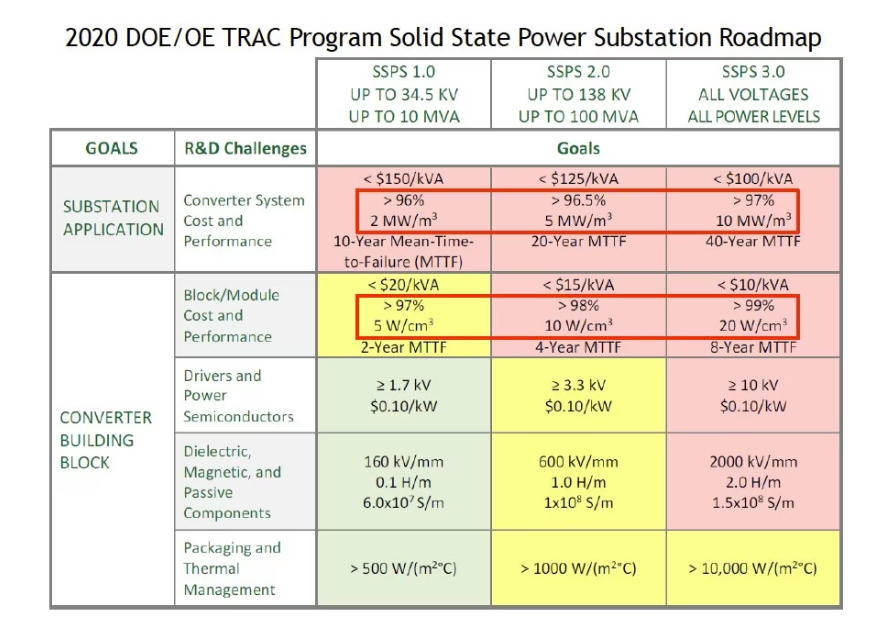

In the U.S., its Power Office's Transformer Resilience and Advanced Components (TRAC) program highlights a future roadmap for all aspects of power generation and distribution. One aspect involves solid-state substations (SSPS). SSPS power converters in substations can be constructed as modular collections of power electronics components. Scalability is a key end goal. The SSPS roadmap (shown in Figure 5) highlights the increasing power density trend from SSPS 1.0 to SSPS 3.0.

Figure 5: Map of solid state substation for DOE/OE TRAC program 2020

Increasing the operating voltage is one of the best ways to increase the power density. The voltage of a battery cell is determined by its chemical composition. Therefore, several cells can be stacked in series to form modules, and then these modules are connected in series to form a cabinet. The cabinets can then be connected in parallel to increase capacity, creating separate systems. A power supply control system (PCS) can be used to control the system and provide voltage to the DC bus.

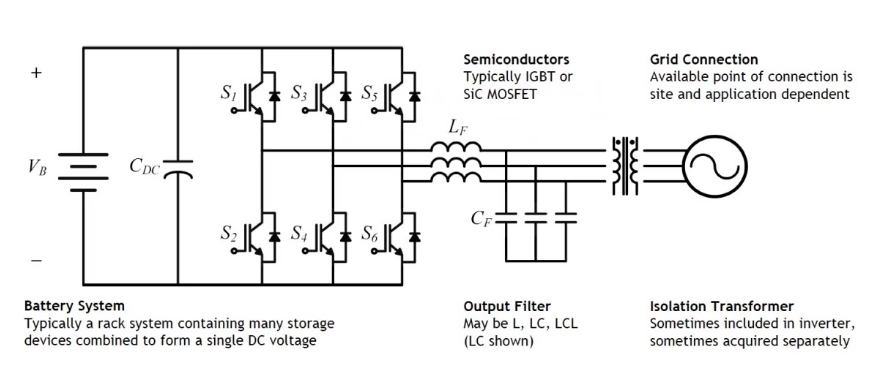

Traditional PCS solutions typically consist of a single-stage inverter, as shown in Figure 6

Figure 6: Traditional single-stage PCS

In this case, the DC bus voltage needs to be greater than the peak AC voltage and leave a certain margin, so the constraint conditions are set. While this single-stage PCS is cheap, it suffers from a lack of scalability. In a battery cell in series, the voltage and current of the cell will change and will change with aging. The weakest cell can become a failure path for the system and thus become a reliability bottleneck. Therefore, this simple single-stage PCS is only used for voltages of 600V or less.

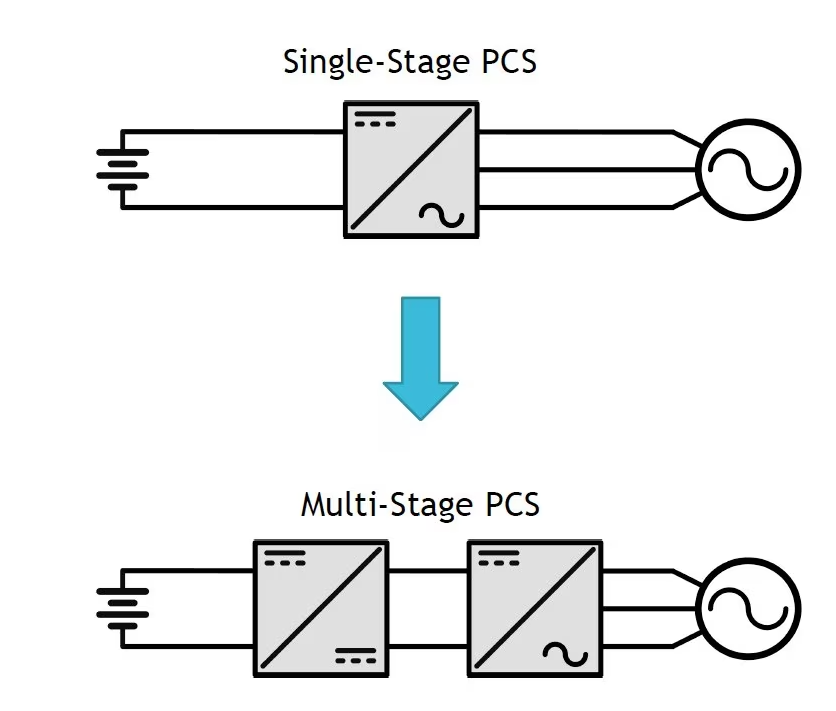

As shown in Figure 7, multistage PCS have the advantage of breaking the voltage constraint of the DC bus. Some of the advantages of multistage PCS are:

● The first-stage voltage is higher, so you can take advantage of higher-voltage SiC devices and multilevel inverter topologies;

● The DC voltage stability is improved, so the capacity of DC bus capacitor can be reduced and the service life can be extended.

Figure 7: Multi-level PCS

Some disadvantages of the multistage approach include higher costs, as well as increased power conversion losses.

It is usually the case that a multilevel inverter is used in each stage. This has several advantages over traditional two-level inverters, including:

● Reduce harmonic distortion;

● Lower switching losses;

● Lower PWM switching frequency;

● Increase the rated power;

● Ability to use devices with lower voltage ratings for higher voltage applications.

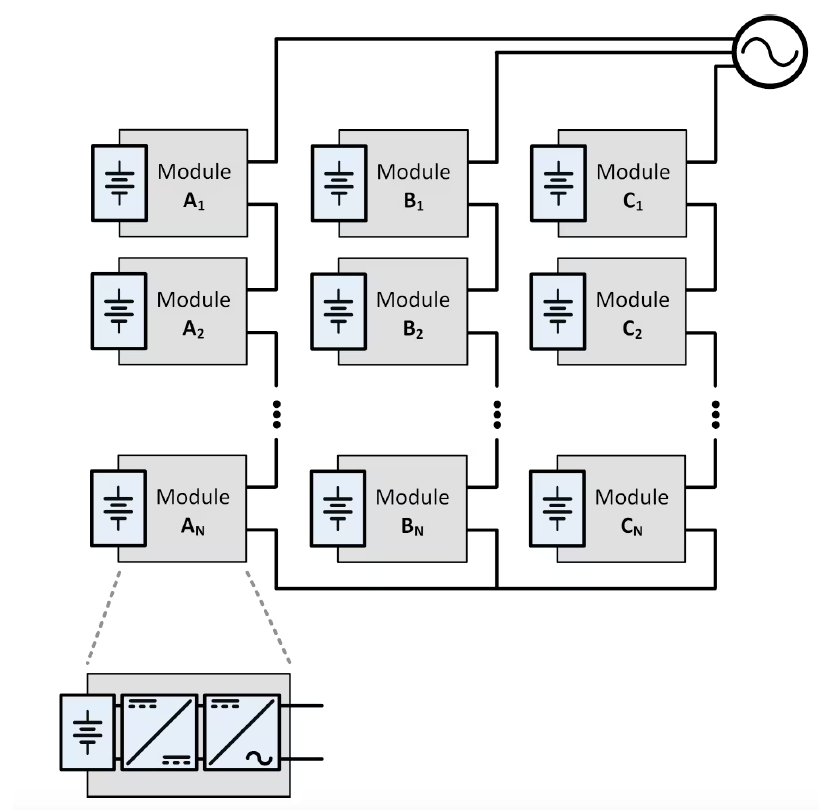

Modularization can be done in a number of ways to improve reliability. Figure 8 shows a parallel PCS. The modules in each parallel branch can be hot-swapable energy storage/converter modules, and the battery parameters in each branch do not need to match exactly. Scalability here is still limited by the voltage gain within each DC/DC converter stage.

Figure 8: Parallel PCS

Figure 9 shows a series connected PCS. It has the advantage of producing a higher DC bus voltage, thus reducing the conduction loss of the cable. This architecture is more tolerant of even small gains in DC/DC converters

Figure 9: cascaded series PCS

Conclusion

SiC based power electronics technology is helping to revolutionize energy storage and grid distribution systems, while making the use of distributed renewable energy generation more practical. Key bottlenecks remain, particularly in terms of long-term energy storage, manufacturing of high-capacity lithium-ion batteries, and passive components such as magnetic components entering the PCS class.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.