Battery-powered devices are an integral part of modern technology, which has completely changed people's lives, allowing many electronic devices to be carried around. For example, medical devices such as blood glucose meters and pacemakers minimize inconveniences in people's lives, devices such as portable power tools and radios can be used for tasks such as disaster relief coordination, and battery-powered devices such as smartphones and laptops used in daily life help people work efficiently and connect to society.

This article will discuss the advantages and challenges of four battery chemical components (lithium ion, lithium iron phosphate, lithium polymer, and nickel-metal Hydride) in battery applications below 30V, and how battery charging ics for these battery types can improve battery performance, uptime, and service life in applications.

Battery charging ics ensure safe battery charging and therefore play a vital role in battery management systems (BMS). It works with voltmeters, battery monitors, and protectors to help protect the battery, monitor its health, and communicate with the BMS in case of problems.

Lithium ion (Li-Ion) battery

Lithium-ion batteries are commonly used in devices such as laptops, electric bicycles, electric vehicles (EVs) and smartphones. This type of battery has a high energy density and a long service life, and the discharge rate is low, which can further extend the time between charges.

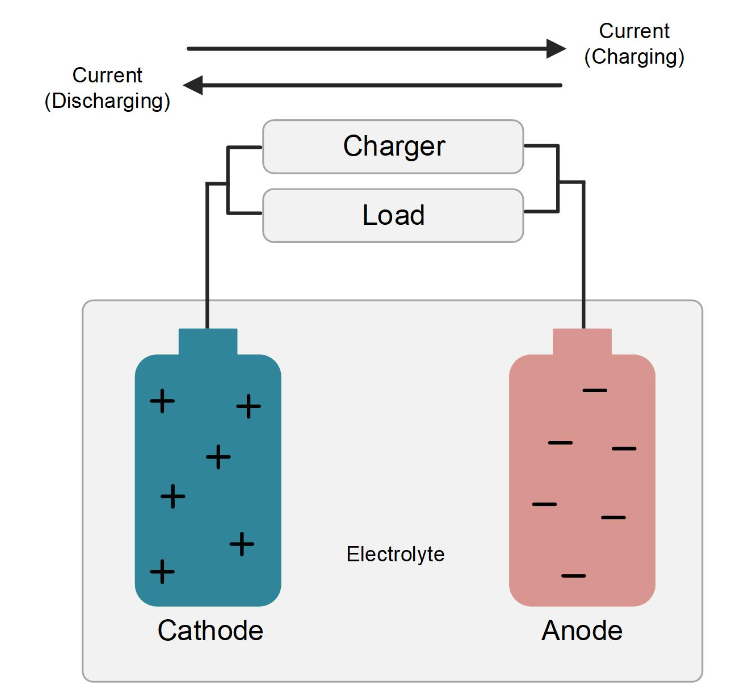

The cathode of the lithium-ion battery is the positive electrode of the battery and is made of lithium compounds; The anode is the negative end of the battery and is usually made of carbon. When a lithium-ion battery is charged, lithium ions flow from the cathode to the anode. Conversely, when it discharges to power the device, lithium ions flow from the anode to the cathode (see Figure 1).

Figure 1: Simplified battery charge/discharge diagram

Lithium-ion batteries also have some drawbacks. For example, when overcharged or discharged, its performance will be reduced; In extreme temperature conditions, they are potentially dangerous and can explode or catch fire.

Lithium-ion battery charging IC

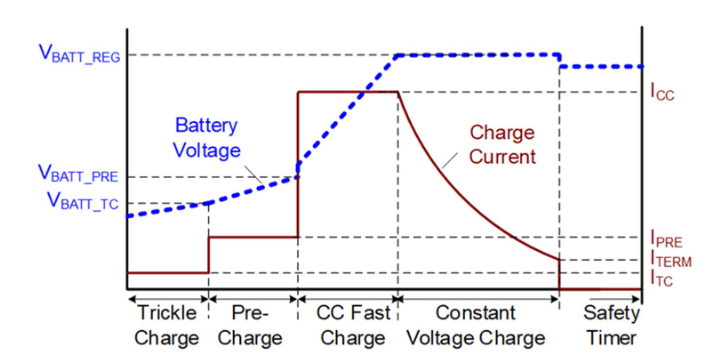

Lithium-ion battery charging ics are used to charge lithium-ion batteries, making them reusable. The lithium-ion charging IC monitors the battery's current, voltage, and temperature to regulate the charging process. It includes the following charging stages:

1. Trickle charging: This stage is usually used when the battery voltage (VBATT) is low, such as when the battery is deeply discharged or disconnected. During trickle charging, the charging IC generates a small current to charge the capacitor of the battery pack.

2. Pre-charge: In this stage, the charging IC begins to slowly charge the battery, so that the VBATT slowly rises at a safe speed.

3. Constant current (CC) charging: CC charging is also known as fast charging, which means that the battery can safely carry more current. The CC charging phase continues until the VBATT reaches full or floating charge voltage.

4. Constant voltage (CV) charging: This stage can ensure the safe operation of the battery. The charging IC monitors the VBATT during CC charging and switches to CV charging once the VBATT exceeds the single-cell voltage in the battery pack.

5. Charging cutoff: Charging cutoff represents the completion of charging, and VBATT begins to decay at this stage.

Figure 2 shows the charging curve of the battery charging IC

The above battery charging curve also applies to other battery types, including all battery chemistry and battery charging ics listed in this article.

Lithium-ion battery charging ics and other lithium-ion related battery charging ics usually also contain some protection features, such as overvoltage protection (OVP), short circuit protection (SCP), and battery voltage protection. In addition, these ics may provide configurable protection thresholds, limits, and parameter values to accommodate a variety of BMS applications.

Take the MP2770, a single-battery switch charging IC that can be used in portable applications such as smartwatches, game controllers, drones, and mobile point-of-sale systems (POS). When connected to an input power supply, the MP2770 operates in charge mode, charging via VBATT in one of three modes: pre-charge, CC charge, and CV charge. When no input is connected, the MP2770 operates in boost mode and is powered by the battery.

The MP2770 incorporates an 8-bit analog-to-digital converter (ADC) that monitors input voltage (VIN), VBATT, system voltage (VSYS), and battery current (IBATT). The MP2770 can also be configured with additional parameters for flexible applications, such as input current limit (IIN_LIMIT), boost voltage (VBST), and protection threshold.

The MP2770 comes in a space-saving QFN-18 (3mmx4mm) package and offers system power path management for a highly integrated battery management system solution (see Figure 3).

Figure 3: Typical MP2770 application circuit

In addition to battery charging ics, lithium-ion batteries and other lithium-ion related batteries can also be part of the battery pack. The battery pack will contain multiple connected cells within a system. In this case, both the battery pack and its battery management system can benefit from coulometers, battery protectors and monitors.

When coulometers (e.g. MPF42791 and MPF42793) are used in conjunction with battery monitors (e.g. MP2790 and MP2797), They can optimize charging and integrate other essential components of the BMS, including current sampling resistors, battery equalizers, State of charge (SOC) monitors for communication while the battery is charged, thereby extending battery life.

Lithium iron phosphate (LFP) battery

LFP batteries are a variant of lithium-ion batteries in which the cathode material is made of iron phosphate, rather than nickel-manganese-cobalt (NMC) or nickel-cadmium (Ni-Cd). Compared to lithium-ion batteries, LFP batteries have a lower energy density and power density. As a result, lithium-ion batteries are more popular for space-constrained applications, while LFP batteries are less common in power tools, e-bikes, laptops, and other low-voltage battery applications. In addition, LFP batteries have a low output voltage (VOUT), which can complicate the power supply design, or require more series cells than lithium-ion batteries to meet the minimum voltage requirements.

But LFP batteries also have obvious advantages. It costs less, is stable over a wide temperature range for safety, and it has a longer life cycle than other battery types and can withstand more charge and discharge cycles. With these advantages and their steady improvement in performance, LFP batteries are also likely to become increasingly popular in low-voltage applications.

LFP Battery charging IC

The charging phase of the LFP battery charging IC is similar to that of the lithium-ion charging IC, which also includes CC charging, CV charging and charging cutoff. LFP battery charging ics can simplify the management of LFP batteries in a battery management system, as they require frequent voltage regulation so that the battery receives power through a USB port or even a solar panel.

The MP2652 is a booster charging IC for power tool applications, designed for 2 to 5 series battery applications (see Figure 4). For safe voltage, the MP2652 provides VIN limiting to prevent input power (PIN) source overload. In addition, the device integrates a 10-bit analog-to-digital converter (ADC) to monitor during charge mode and source mode.

Figure 4: MP2652 typical application circuit

The MP2759 is another booster charging IC for industrial medical devices. Designed for 1 to 6 series battery pack applications, it operates at a maximum voltage of 36V DC VIN and has OR power path management for reliable battery charging via an external switch (see Figure 5).

Figure 5: MP2759 with OR power path management

When connected to the input power supply, the MP2759 charges the battery through four stages: trickle charge, pre-charge, CC charge, and CV charge. Its protection features include battery OVP, overtemperature shutdown protection and charge safety timer. The MP2759 also provides status pins to display power and operating status for improved visibility. The MP2759A is similar to the MP2759, but it offers a narrower negative temperature coefficient (NTC) window.

Lithium polymer battery

Lithium polymer batteries are commonly used in portable devices such as smartphones, tablets and wearables. The cells are thin, come in a variety of shapes and sizes and can be adapted to many different applications.

The anode and cathode of a lithium-polymer battery are similar to those of a lithium-ion battery, but the electrolyte that enables lithium ions to flow between the anode and cathode is different. Lithium polymer batteries use solid polymer electrolytes, which are more flexible and help reduce weight.

Lithium polymer batteries also have a lower self-discharge rate and a higher energy density, so they can maintain stored energy and provide longer battery life. However, any physical damage or overcharge/discharge can cause the battery to swell or even catch fire. In addition, the battery is not highly standardized, so sometimes it cannot be applied to different devices.

Lithium polymer battery charging IC

The function of the lithium polymer battery charging IC is similar to that of the lithium ion/lithium iron phosphate battery charging IC. Not only do they have the same charge curve, but they also have the advantages of voltage and current regulation, safety protection, and smart charging algorithms that prevent overcharging and overheating. These characteristics effectively extend the service life of lithium polymer batteries.

Charging ics compatible with lithium-ion batteries are also compatible with lithium-polymer batteries, such as the MP2770, MP2652, and MP2759.

Nickel metal hydride (NiMH) batteries

Nickel-metal hydride batteries are commonly used in digital cameras and portable power tools. Unlike standard batteries, NIMH batteries can be recharged and reused.

Nickel-metal hydride batteries have a nickel-based cathode, a hydrogen absorbing alloy, and an alkaline electrolyte to facilitate the flow of ions between the anode and cathode.

Nickel-metal hydride batteries have a high energy density and low self-discharge rate, so they can maintain charge for a long period of inactivity. But the battery can only provide 1.2V per cell, which limits its range of applications; And incomplete charge/discharge cycle will also have a negative impact on its optimal charge/discharge capacity.

Nimh battery charging IC

Although the chemical composition of nickel-metal hydride batteries and lithium batteries is completely different, their charging ics follow the basic rules of all charging ics, that is, both can provide a variety of protection for the battery and battery charger, and realize parameter monitoring and configuration functions. The NIMH battery charging IC can also track changes in the VBATT, thereby regulating the charging process.

The MP270x family of devices, including the MP2700, MP2702 and MP2703, are linear battery charging ics that can be used in 2 to 6 nickel-metal hydride battery applications. Each charging IC in the family has a withstand voltage of up to 26V and charges the battery in four stages: trickle charge, pre-charge, CC fast charge and CV charge.

Users can select the right charging IC features for their application, such as PIN monitoring (MP2702 and MP2703), charging status indication (MP270x series), and enabling (EN) pins that enable the entire chip (MP2702). Memory can also be selected to configure parameters such as input current limit (IIN_LIM), minimum VIN limit, and battery full charge voltage. Figure 6 shows a typical application circuit for the MP2702.

Figure 6: MP2702 typical application circuit

Conclusion

Battery-powered devices have changed the way people connect to the world, and the way they are charged is critical to their functionality and lasting use. This paper discusses a variety of battery chemical components and their effects on low-voltage system battery management systems (BMS).

Although batteries all follow common charging specifications, differences in chemical composition make their typical applications different, so compatible charging ics are required to ensure their safety and efficiency. But even charging ics that are suitable for the same battery chemistry may be suitable for different applications, for example, the MP2652 is ideal for power tools, while the MP2759A is ideal for medical devices.

MPS offers a broad portfolio of battery charging ics, including linear battery charging ics and charging ics with 3 or more series batteries, which cover almost every application. For the cells in the battery pack, MPS also provides voltmeters, battery protectors, and monitors to provide additional protection and functionality to optimize the overall performance of the BMS.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.