When we talk about time-of-flight (ToF) technology, the most important thing to consider is embedded vision technology, which has changed dramatically over the years. From its first theoretical formation in the 1970s until today, the technology's leap forward has ushered in a new era of advanced imaging for autonomous mobile robots (AMR). The most common use of AMR is in industrial warehouses, where ToF technology plays a key role in helping robots sense their surroundings with optimal accuracy.

What is ToF technology?

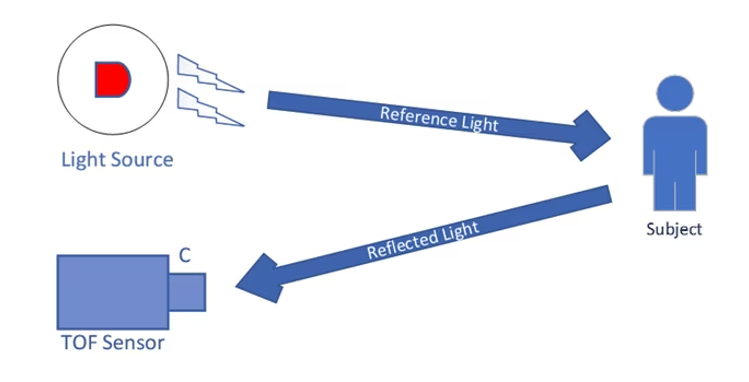

ToF calculates the time it takes for an object, particle, or wave to travel from point A to point B. Fundamentally, ToF technology is similar to sonar. ToF calculates the distance between objects by measuring the time it takes for the signal to be transmitted from point A to return to the detector of the signal source after being deflected from the object. Typical signals used by ToF technology are acoustic and optical signals. Sensors that use light signals do this by calculating the time it takes for light to reflect from an object back to the signal source.

How does it work

ToF camera systems use an illuminated light source (usually a laser diode or LED) and a sensor to measure distance. The light source sends out A pulse, and the sensor pixel measures the time it takes for the light to return and determines the distance to the object (i.e., point A) based on the round-trip length.

Key components of the ToF camera system

How is ToF technology revolutionizing mobile robotics

Modern stereo vision technology is applied by using infrared pattern projectors to illuminate the surrounding environment or scene, thus comparing the differences in images from 2D sensors to provide a high level of low light performance to determine the range or distance of an item. In contrast, ToF technology goes a step further, using sensors, lighting units, and depth processing units to calculate the depth of a mobile robot.

As a result, they can be used out of the box without further calibration. When performing scenario-based tasks, ToF cameras are placed on mobile robots to extract 3D images at high frame rates and quickly segment the background or foreground. Since ToF cameras can also use active lighting components, mobile robots can perform tasks in bright conditions or in complete darkness.

How do ToF cameras measure depth

ToF driven mobile robots in automated warehouses

The role of ToF cameras in warehouse operations is clear. These cameras are used to equip AMRs and automated guided vehicles (AGVs) with depth-sensing intelligence. They can help these devices sense their surroundings and capture imaging data in depth to perform critical business functions accurately, easily and quickly. Features include:

Surveying and mapping

These cameras map an unknown environment by measuring the transit time of light reflected from an object to a light source. It uses real-time localization and Map Building (SLAM) algorithms that require 3D depth perception to achieve accurate mapping. Using 3D depth perception, for example, these cameras can easily create predetermined paths within a field for the robot to move around.

Navigation

Amrs prefer to move from point A to point B on a given map, but with the SLAM algorithm, they can also do so in unknown environments. If ToF technology is successfully utilized, AMR can quickly process information and analyze its environment in 3D before deciding on a path.

Obstacle detection and avoidance

The AMR is likely to encounter obstacles when traveling in the warehouse, so it is a priority to equip it with the ability to process information quickly and accurately. With these sensor-based ToF cameras, the AMR can re-determine its path if it encounters an obstacle.

Orientation

Typically, ToF cameras help AMR identify objects on known maps by scanning the environment and matching real-time information with pre-existing data. This requires a GPS signal, but this is a challenge for indoor environments such as warehouses, so another solution is a locally-operated location feature. Using ToF cameras, they can capture 3D depth data by calculating the distance from reference points in the map. The AMR can then use triangulation to pinpoint its exact location. This enables seamless positioning, making navigation simple and secure.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.