Technology companies and major semiconductor manufacturers are actively seeking ways to minimize their carbon footprint and thus achieve net zero greenhouse gas emissions. Under the 2015 Paris Agreement, the goal is to limit global warming to 1.5°C by 2050.

Unfortunately, if we continue on our current path, global warming is projected to reach 1.9-2.9°C, with significant negative impacts on the global economy. To combat this, companies are investing in research and adoption of net-zero technologies for industrial manufacturing to effectively reduce carbon emissions from manufacturing processes.

This paper explores the solutions recommended by various electronics and semiconductor manufacturing companies to enhance CO2 reduction in the industrial sector.

ADI sees two key areas to focus on

In terms of accelerating the reduction of CO2 emissions in the industrial sector, ADI recommends focusing on the following two areas.

1. Increase energy efficiency by increasing the deployment of motor drives

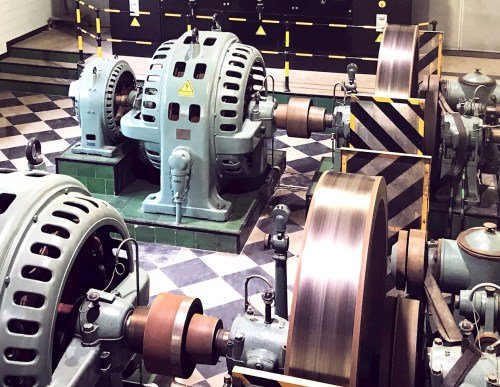

According to the company's report, optimizing the efficiency of all motor drive systems in industrial environments could reduce global electricity demand by 10 percent and eliminate 2.49 billion tons of carbon dioxide emissions by 2030. These motors, shown in Figure 1, are used in various industrial fields, such as driving pumps, fans, compressed air systems, material handling, processing systems, and more.

About 70-80% of current motors are connected to the grid and can be connected to inverters or variable speed drives (VSD) to reduce energy consumption. Create an inverter with adjustable frequency and voltage output by integrating rectifier, DC bus and three-phase inverter. This inverter helps the motor to operate at optimal speeds for specific loads and applications, resulting in significant energy savings.

In addition, the implementation of intelligent motion control solutions will further contribute to the reduction of energy consumption. This can be achieved through the use of high-efficiency motors and VSD in various applications.

The International Electrotechnical Commission (IEC) has also played an important role in setting standards for high-efficiency motors. These standards include the motor energy efficiency test standard IEC 60034-2-1 and the motor energy efficiency rating standard IEC 60034-30-1, which will classify motors into four energy efficiency grades IE1-IE4.

Figure 1: Motor drive system

2. Digital transformation strategy to improve manufacturing efficiency

By integrating information technology and operational technology on the Ethernet, sports applications can be seamlessly connected, enabling the exchange of valuable data and sports insights. VSD is essential for collecting data from a variety of sources while using external sensors to monitor variables such as vibration and process parameters.

These insights can be securely stored in the cloud or at the edge, opening up opportunities for in-depth analysis using advanced AI techniques. Using this data, manufacturers can optimize their production processes, significantly reducing energy consumption and CO2 emissions throughout the manufacturing stage.

The industry is experiencing a convergence of advanced technologies, including edge computing, signal processing, and connectivity solutions. These advances allow them to collect motion data and generate valuable insights at the intelligent edge. These insights are then transmitted to the manufacturing execution system for analysis and follow-up.

In large manufacturing plants where multiple motors are deployed, implementing digital transformation strategies is critical to effectively reduce electricity consumption and minimize CO2 emissions.

ABB Energy Assessment helps improve energy efficiency

The use of the Internet of Things and digitization has played an important role in reducing energy consumption while unlocking new business prospects. These technologies facilitate remote connectivity, allow equipment status and manufacturing processes to be updated in real time, and enable businesses to make informed decisions about energy efficiency.

Interestingly, a chart from ABB highlights the total cost of ownership for motor drive systems, showing that electricity accounts for 70% of the total cost. In contrast, motor purchases account for only 5% and motor repairs 20%, as shown in Figure 2.

Figure 2: Total cost of ownership for motor systems

ABB has launched the Energy Assessment Program to provide detailed insights into how motor drive applications operate and help companies make informed decisions about ways to save energy and reduce CO2 emissions. The solution works efficiently whether the device is connected to a network or not.

In offline mode, engineers must conduct site visits to collect data from various installed components, such as motors, drives, generators, pumps, and other applicable systems. The collected data is then carefully analyzed to assess the potential for energy savings and subsequent reductions in CO2 emissions. The engineering team will also calculate the estimated payback period for motor and drive investments. Once the recommended measures have been implemented, the savings can be closely monitored and validated to ensure they are consistent with the original projections.

Instead, online processes leverage remote connections to automatically collect data, generating data-driven insights that can be used to minimize power consumption. In the past, motor systems were often optimized in isolation, but modern solutions go beyond this limitation by providing a holistic view of the entire application. This gives companies a complete picture of their operational performance and energy efficiency.

The adoption of digitally connected services will accelerate the achievement of energy efficiency targets by generating data-driven insights that will enable actionable measures in line with international climate agreements.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.